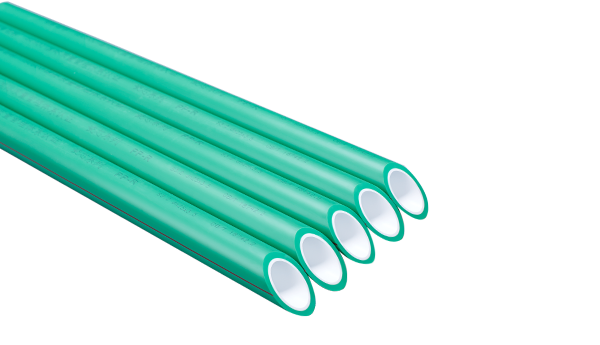

RIFENG PP-R plumbing system, made out of high-quality polypropylene random copolymer, can be utilized in both residential and commercial buildings.

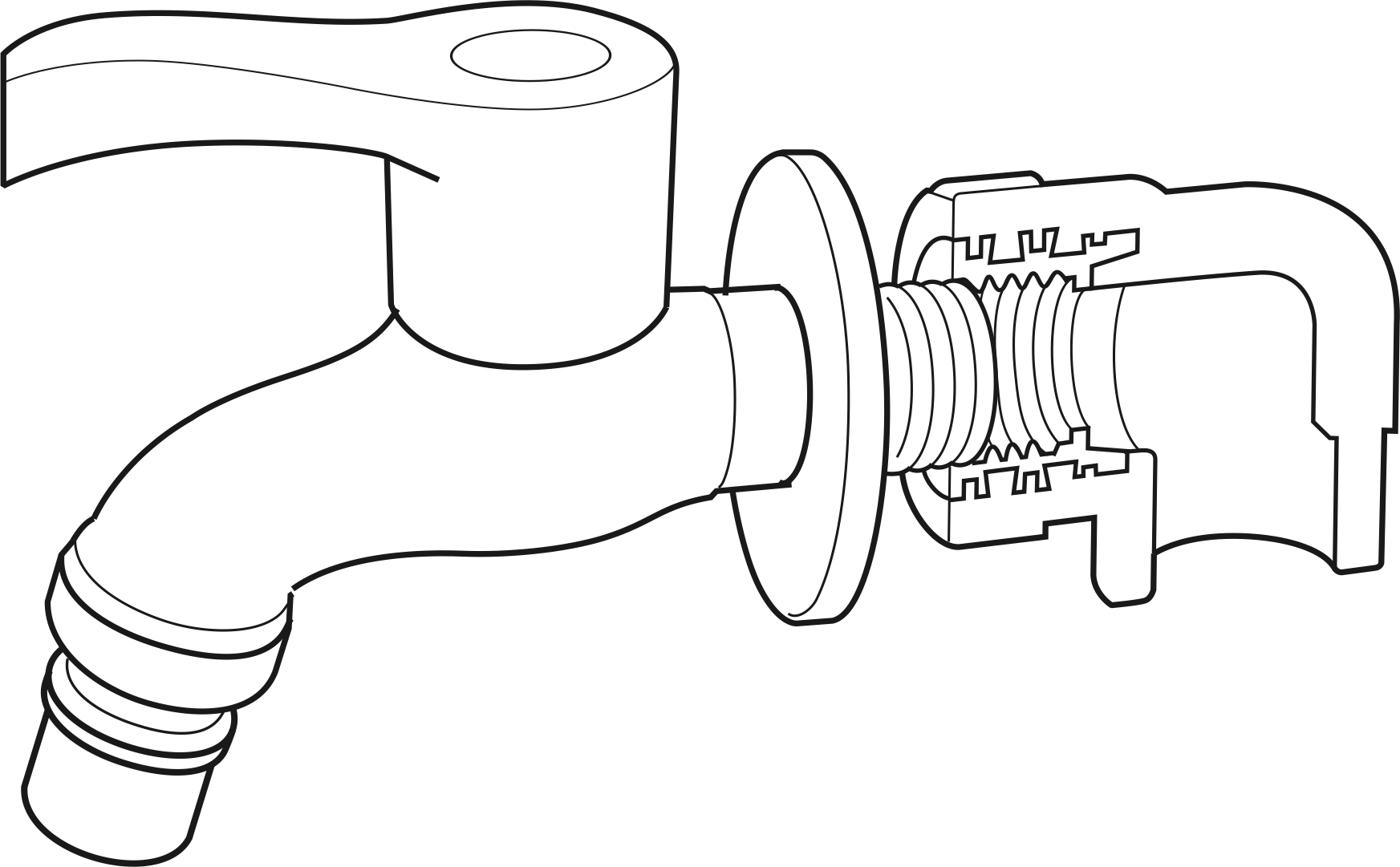

• Full diameter, water flow increases by 200%.

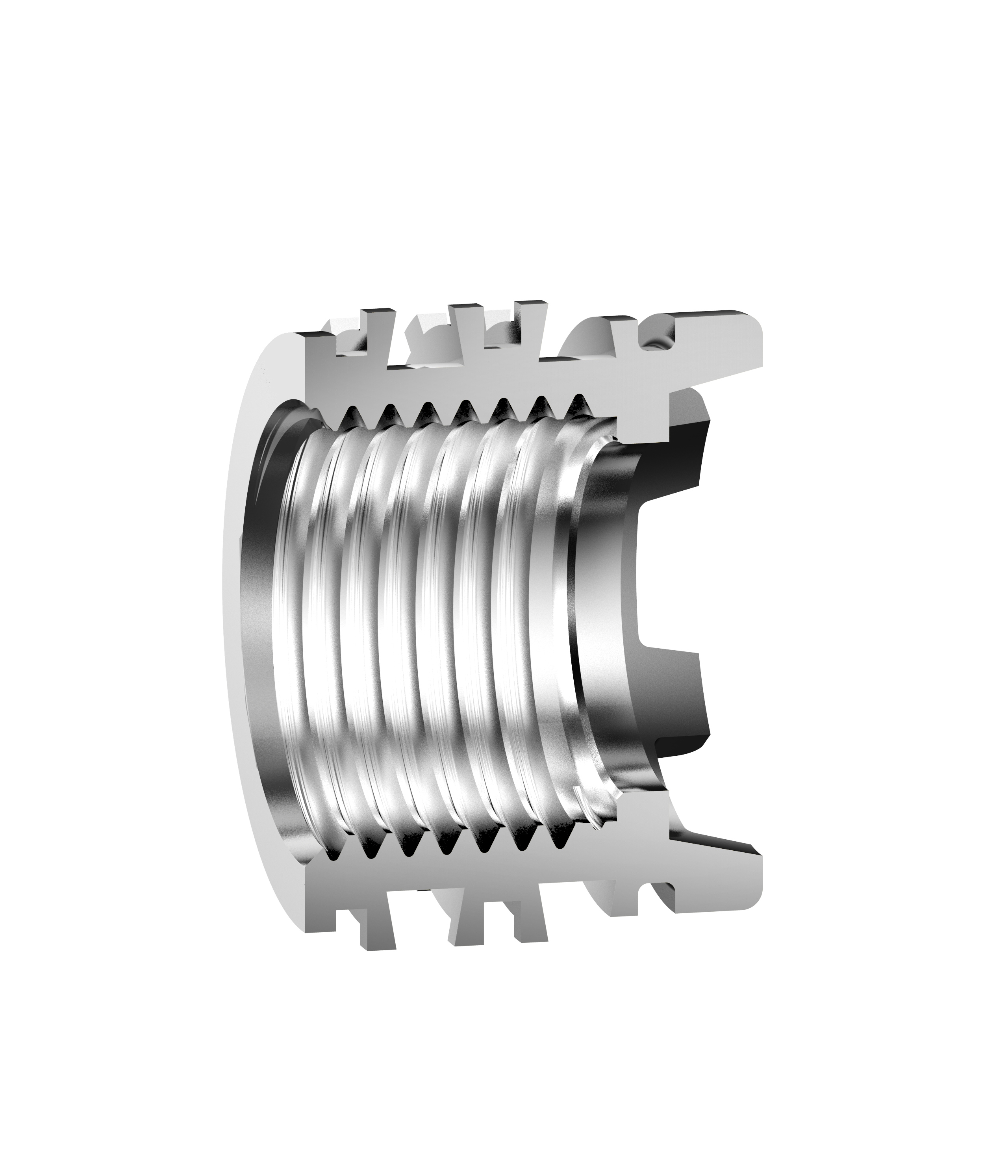

• Three NBR seal rings to prevent leakage.

• High-quality brass of the valve spool, which makes it more durable.

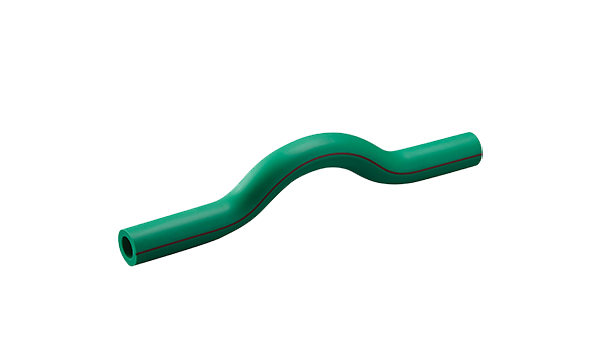

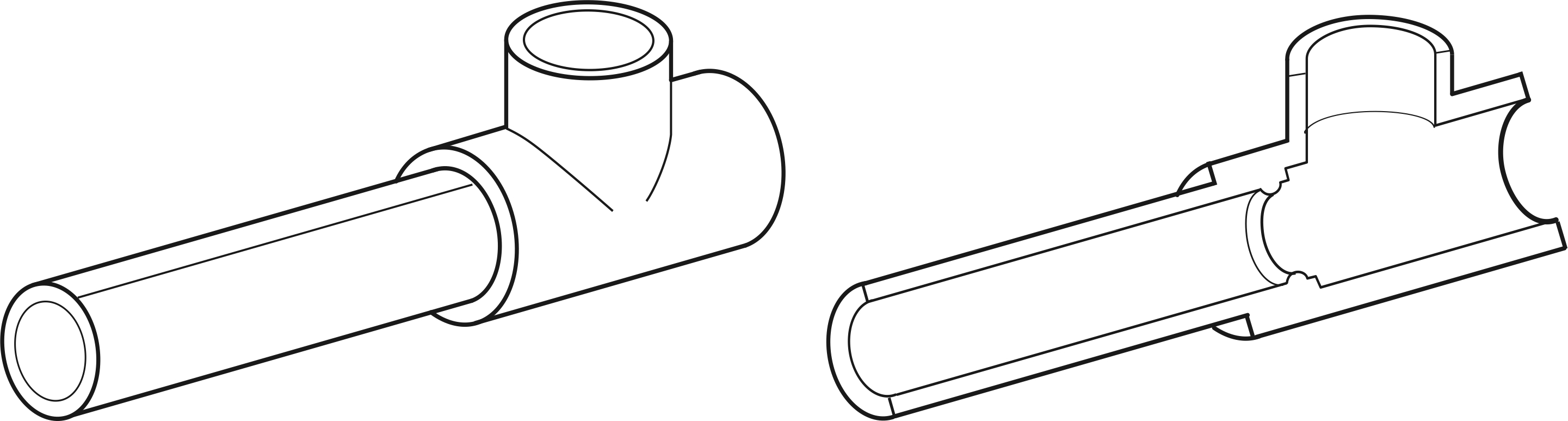

• The new U-profile tap elbow is ideal for hygiene-focused and water flow rate-optimized installations utilising various loop installation methods.

• Improved profile design allowing better flow rate.

• Easier and more adaptable installation.

• Reducing 50% of the water resistance,with twice the arc,the water flow impact pressure wave is scattered and disappeared by the curved surface.

• Meanwhile, it avoids directly striking the fitting and causing damage.

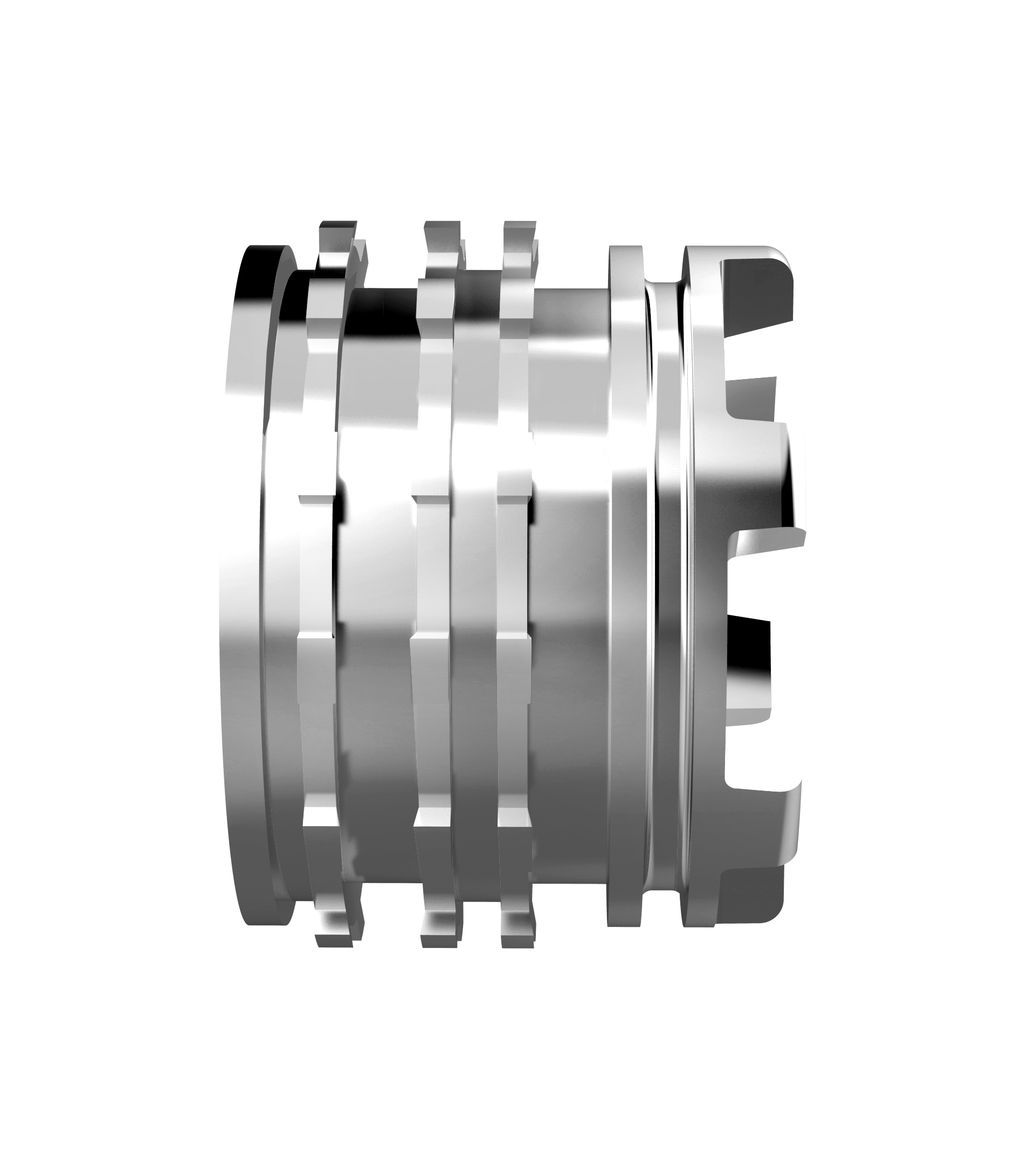

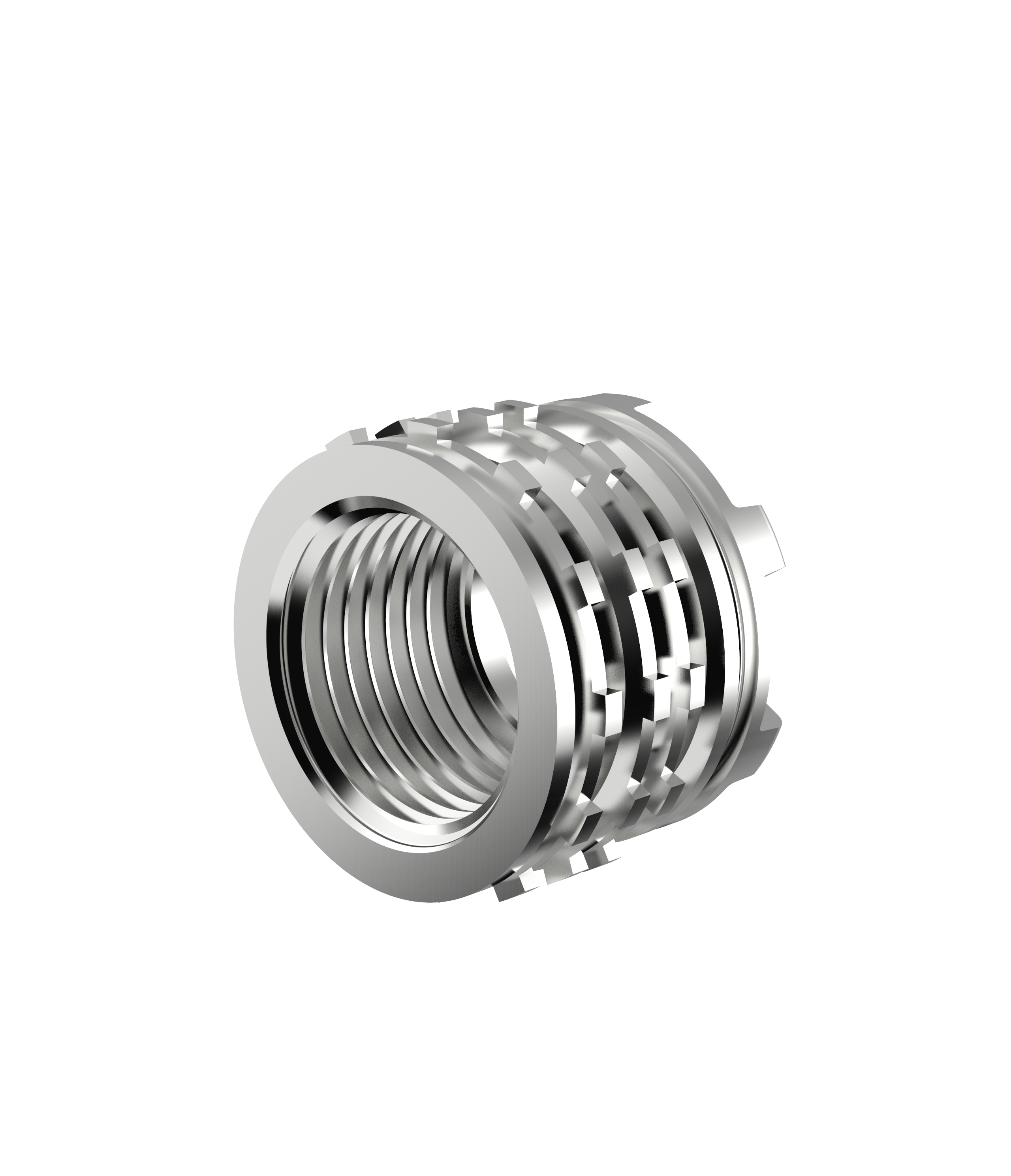

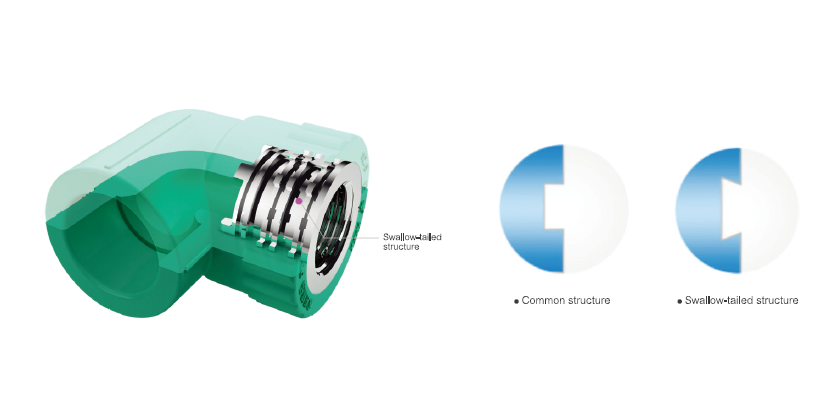

• The swallow-tailed structure ensures zero leakage,excellent air-proof performance and safer connections.

• 12 anti-skid teeth and 36 occlusion points to ensure that the metal and plastic parts are inlaid tightly.

• Multiple techniques enhance the pressure resistance and flexibility.

• The check ring is designed to prevent overtwisting.

• Sand-blasting process with high precision.

Technical specification

• Applied for potable water pipeline system with hygienic and non-toxic features.

• High temperatures and high pressure resistant.

• Heat preservation and energy saving during the flow.

• Lighter and more smoother than the metal pipe.

• The reliable and convenient connecting pipes and fittings by homogeneity melt.

• Notice free at high flow rates.

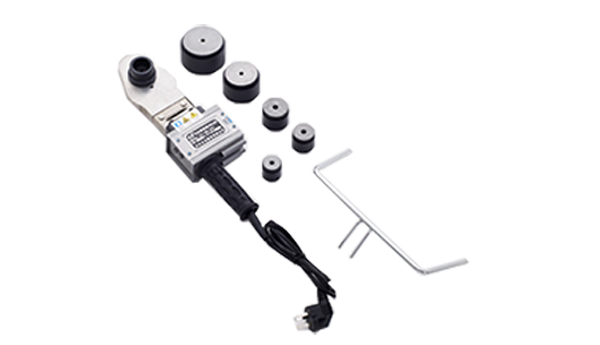

• Fusion technology's speed and ease of use.

• Significant time and labour savings.

• A long lifespan up to 25 years under normal conditions.

RIFENG PP-R piping system can be used in following applications:

• Cool and hot water distribution

• Pipes for connecting various types of low-temperature heating systems

• Pipes for solar energy system heating and cooling settings

• Cold water piping for air conditioners

• Potable water, hot and cold water, chemicals, irrigation

• Apartments, condominiums, and public housing

• Commercial shopping malls, as well as office buildings

• Chemical and food processing manufacturing plants

• Hospitals

• Schools, laboratories and chemical sewerage

• Hotels and resorts

NSF /ANSI /CAN 61 – about Health Effects of Drinking water system components

DVGW W 544 – about PP-R pipe general mechanical requirement

DVGW W 270 – about Hygienic property of material

UBA KTW – about Hygienic property of material odor test

DIN 8077 – about Polypropylene pipe dimension

DIN 8078 – about Polypropylene pipe general quality requirement and testing

EN ISO15874 – about Plastic piping system for hot and cold water installation

Certificates:

NSF – from USA, refers to NSF /ANSI /CAN 61

DVGW – from German, refers to DVGW W 544,UBA KTW,DVGW W 270

AENOR – from Spain, refers to EN ISO 15874

CE – from Europe, refers to EN ISO 15874

ISO 9001:2015 – “Quality management system”

ISO 14001:2015 – “Environmental management system”

ISO 45001:2018 – “Occupational health and safety management system”

| TYPE | PPR Pipe | PVC Pipe | Copper pipe |

| Roughness(μm) | 0.4~1.0μm | 1.5mm | ≥2.0μm |

| Melting point (℃) | 145 | No obvious melting point, softening point around 85℃ | >900 |

| Density (g/cm3) | 0.89~0.91 | 1.42 | 8.96 |

| Modulus of elasticity (MPa) | 800 | 2900-3400 | 105-137 GPa |

| Thermal conductivity (w/mK) | 0.24 | 0.16 | 388~391 |

| Coefficient of thermal expansion (mm/mK) | 0.15 | 8*10-5 | 0.017 |

| Property | Test Method | Unit | Value |

| Melt Flow Rate | |||

| MFI 190/5 | ISO 1133 | g/10 dk. | 0.5 |

| MFI 230/2.16 | ISO 1133 | g/10 dk. | 0.3 |

| MFI 230/5 | - | g/10 dk. | 1.5 |

| Density at 23℃ | ISO 1183 | g/cm3 | 0.9 |

| Tensile Stress at Yield | ISO 527 | Mpa | 25 |

| Elongation at Break | ISO 527 | % | >50 |

| Modulus of Elasticity, Tensile Test | ISO 527 | N/mm2 | 900 |

| Impact Strength (Charpy) | |||

| 23℃ | ISO 179/1eU | Kj/m2 | No failure |

| 0℃ | ISO 179/1eU | Kj/m2 | No failure |

| -10℃ | ISO 179/1eU | Kj/m2 | No failure |

| Notched Impact Strength (Charpy) | |||

| 23℃ | ISO 179/1eA | Kj/m2 | 20 |

| 0℃ | ISO 179/1eA | Kj/m2 | 4 |

| -10℃ | ISO 179/1eA | Kj/m2 | 3 |

| Coefficient of Linear Thermal Expansion | DIN 53 752 | K-1 | 1.5×10-4 |

| Thermal Conductivity at 20℃ | DIN 52 612 | W/mK | 0.24 |

| Specific Heat at 20℃ | Adiabatic Calorimeter | Kj/kg K | 2 |

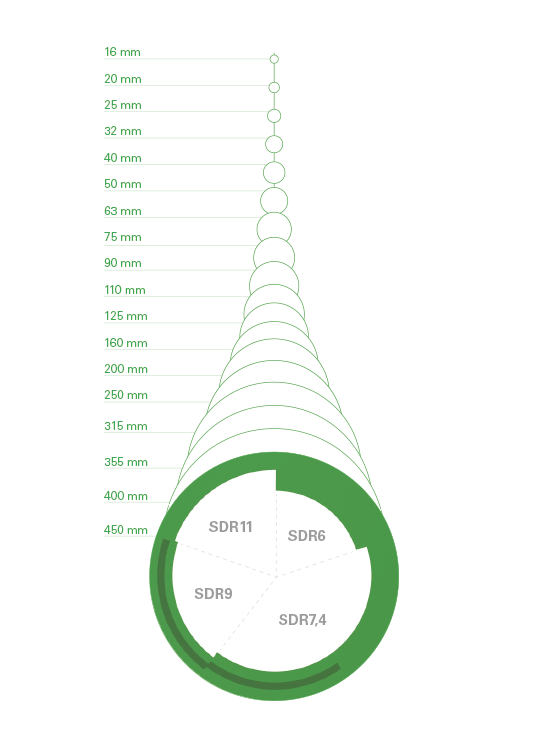

RIFENG PPR pipe provide the following SDR-sizes:

- SDR6

- SDR7.4

- SDR9

- SDR11

Homogeneity melting provides reliable connection strength and sealing property between PP-R pipes and PP-R fittings.

Metal thread connection

Rifeng holds the exclusive patent to manufacture these fittings.

SWALLOW TAILED NOTCH 36 BITING POINTS BUTTON SAFETY RING